How to Choose Materials for Custom Tuck Boxes

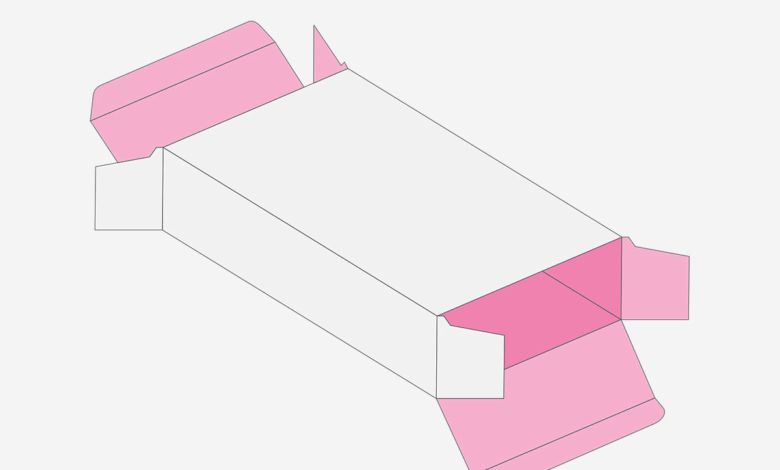

A tuck box is a type of folding carton with flaps that “tuck” into the body of the box to close it securely. Tuck boxes are commonly used to package products like cosmetics, food, retail items, and promotional goods.

Tuck boxes are a popular medium for packaging products due to the versatility they provide. They are easy to assemble and are fairly priced considering they are a very efficient packaging solution. The type of material you end up choosing to make these boxes should be able to perform the function you intend for it to do.

In today’s guide, we will be exploring different factors that should be considered when choosing a material for your custom tuck box. In this guide, as we learn about different materials, we will also discuss the pros and cons of the materials we discuss. We’ll be discussing how certain materials affect the strength and look of your boxes and select the best one for your specific needs.

What factors should you consider when choosing material for a tuck box?

1- Product type and weight

The type of material you end up choosing depends on many factors, the first thing you need to consider is the type of product you are looking a box for and how much the product weighs. Light products, e.g. small electronics, cards, or cosmetics require a light material like paperboard while on the other hand, heavier items such as bottles, tools, or larger products may require a more durable material such as corrugated cardboard.

Lightweight options

Paper Board (or chipboard)

Paper board is the most common way tuck boxes are made, it’s for light products. The paperboard is thin, but it is good enough for small products.

Heavyweight options

Corrugated Cardboard

Corrugated Cardboard is layered, which makes it a stronger option than paper board. If your product is on the heavier side, you should go with the more study option in corrugated cardboard.

2- Durability and Protection

As a business, the last thing you want is a customer returning their order because the product arrived in a broken state. To avoid this, you want your box to be as durable as possible. Your box should be able to protect the contents inside it from damage it may receive during shipping, handling, and storage.

PaperBoard

Paperboard, as the name suggests is not very thick, Paper board is good enough for light products but not as tough as corrugated cardboard. It’s usually the box products like poker cards, and medicines come in.

3- Appearance and Printing Capabilities

Your boxes not only serve the purpose of storing the product but they also serve as a marketing tool, this only means when designing a design for your boxes keep in your mind that visual appeal is very important. All materials have different surfaces so it is important to choose the right material

If your product requires the box to be vibrant, coated paperboard is the best material for you. The coated paperboard is smooth and is a perfect material for quality printing.

Conversely, Kraft paper gives off a very organic and rustic look. Kraft is perfect for a brand that has a very eco-friendly approach. Unlike, Coated paper wood the texture isn’t smooth and provides a very unique texture.

4- Budget

As we have previously discussed, there are a lot of options all with varying prices. So you have to do your research on which products fit your needs financially. Paperboard is one of the most affordable options, it offers a decent balance between durability and printability. It’s a good fit for small or medium-sized orders.

Corrugated cardboard is strong and is fit for bigger and heavier products, it’s expensive but it can be a great investment considering its heavy-duty packaging, especially for larger or more fragile products.

If you are a premium brand that offers luxurious products for instance watches, wine or any other product that needs that extra bit of flare, Textured coated paper can be a good fit for your needs.

5- Environmental Impact

Global warming, which was once an idea is now something we can witness doing damage to our earth, Users are now more aware of their actions and thus love playing their part in saving the environment. An eco-friendly package can not only improve your brand image but also contribute to a much larger cause i.e. saving the earth.

Kraft is made from recycled materials, it is natural and a biodegradable material. Recycled paperboard is also made from materials that have been disposed of by the consumer, which involves materials like paper, plastic bottles, aluminum cans, and glass bottles.

Soy-based inks and water-based coating for printing are also used for sustainable products. Both of these are more eco-friendly than the inks we are accustomed to.

6- Custom features and functionality

If you want to customize your tuck box, for instance, you are selling a toy that must be visible even when it’s inside the box, you need to choose certain materials that are better suited for these features:

· Windows or die-cutting:

Paperboard is perfect for die cutting, it is easy to cut through which makes it possible to add custom cut-out shapes, windows, or unique designs to your boxes.

· Compartments

If you want to include an insert or divider inside your box, corrugated cardboard is usually the material best suited for this approach. Since it is sturdier, it holds its shape allowing it to support additional components inside the box.

7- Shipping and storage

Now, we need to factor in the fact that your box will be travelling across the world, and for that, you need your box to be tough. Think about how your packaging logistics will be affected by the material you select Compared to corrugated cardboard or Display Boxes, paperboard is smaller and lighter. This can lower the total cost of transportation and the amount of storage space required.

Although corrugated cardboard is heavier, its strength guarantees that goods are adequately safeguarded while being transported. Purchasing thicker cardboard is a smart choice if your items require more maintenance. Choosing the right material for your tuck box is critical to ensure your products are well-protected, visually appealing and align with your brand’s values. By considering the factors we have talked about in this guide, you can select the best material to suit your specific requirements.