If Evaporator is Flooded, the Superheat Will Increase: A Deep Dive into the Effects on Refrigeration Systems

Understanding the Impact of Flooded Evaporators on Superheat, System Efficiency, and Compressor Protection

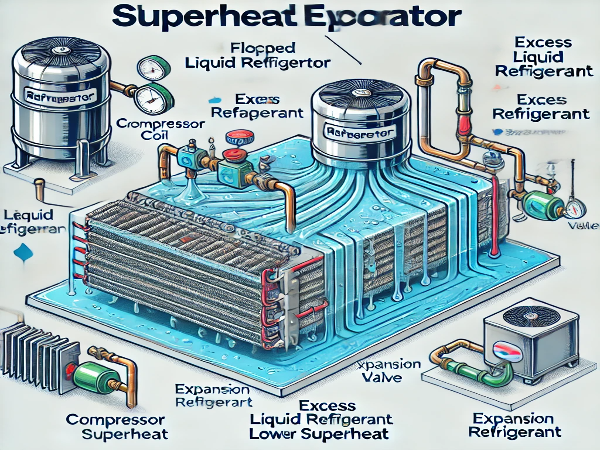

If evaporator is flooded, the superheat will increase. This statement holds particular significance in the world of refrigeration systems, as understanding the relationship between superheat and evaporator flooding is crucial for system efficiency and performance. A flooded evaporator occurs when the amount of refrigerant entering the evaporator exceeds the capacity of the system to fully vaporize it. As a result, more liquid refrigerant remains in the evaporator coil, which can lead to changes in superheat and potentially cause issues with system functionality. This article delves into how a flooded evaporator affects superheat, offering insights into its implications for refrigeration system efficiency, compressor health, and the safe operation of HVAC systems.

Introduction: The Role of Superheat in Refrigeration Systems

In refrigeration systems, maintaining proper superheat is essential for both efficiency and the protection of key components like the compressor. Superheat refers to the temperature of the refrigerant vapor above its boiling point at a specific pressure. It serves as an important indicator that the refrigerant has been fully vaporized before it enters the compressor, preventing potential damage from liquid refrigerant. Superheat is determined by several factors, one of the most important being the performance of the evaporator.

The evaporator is a critical component of the refrigeration cycle, where heat is absorbed from the surrounding environment, causing the refrigerant to evaporate. When the refrigerant enters the evaporator, it begins as a liquid and absorbs heat, transitioning into a vapor. The amount of superheat is directly related to how much heat is added to the refrigerant as it moves through the evaporator.

But what happens when an evaporator is flooded, meaning there is excess liquid refrigerant present? Does the superheat increase or decrease, and what does this mean for system performance? This article will explore these questions in depth, focusing on the effects of a flooded evaporator on superheat and the subsequent implications for the system’s overall operation.

Understanding Superheat and Evaporator Performance

To fully understand how superheat behaves in a flooded evaporator, it’s essential first to grasp the basics of how superheat is measured and controlled. Superheat is the temperature of the refrigerant vapor above its boiling point at a given pressure. A refrigeration system’s superheat level is determined by measuring the temperature difference between the refrigerant vapor and its corresponding saturation temperature at the same pressure.

In an ideal refrigeration system, the refrigerant should enter the compressor as fully vaporized, with just enough superheat to ensure no liquid refrigerant reaches the compressor. Liquid refrigerant in the compressor can cause severe damage, so controlling superheat levels is key to preventing this risk.

Evaporators are designed to absorb heat and cause the refrigerant to evaporate. Depending on the design and flow of refrigerant, the system can operate in various superheat conditions. Systems with a dry evaporator, where little liquid refrigerant is left at the evaporator exit, typically see higher superheat levels. Conversely, in a flooded evaporator, there is excess refrigerant entering the evaporator, leading to lower superheat levels due to more liquid refrigerant remaining in the evaporator.

What Happens When an Evaporator is Flooded?

When an evaporator is flooded, it means that more refrigerant is entering the evaporator than can be fully vaporized. This can occur in systems where the refrigerant flow rate is too high, or the evaporator is oversized for the system’s capacity. In such cases, liquid refrigerant accumulates in the evaporator, causing an imbalance in the system. While the excess liquid refrigerant does absorb heat as it evaporates, some liquid remains in the coil, leading to a lower superheat.

Flooded evaporators typically result in reduced superheat levels because the refrigerant remains closer to its saturation point, meaning that it has not absorbed enough heat to increase its temperature above the boiling point significantly. This condition allows for better heat transfer in the evaporator, but it can cause issues if not carefully managed.

However, if the system is not properly adjusted to handle this excess liquid, it can lead to improper vaporization and insufficient heat transfer, resulting in poor cooling performance. Additionally, flooded evaporators can lead to compressor damage if liquid refrigerant reaches the compressor, which is why maintaining appropriate superheat is crucial for safe and efficient operation.

The Effects of Flooded Evaporators on System Efficiency

The efficiency of a refrigeration system is closely tied to the superheat level. In systems with a flooded evaporator, the excess liquid refrigerant can contribute to more efficient heat transfer, as the evaporator operates in a more saturated state. The increased liquid refrigerant in the evaporator means that more of the evaporator coil is filled with refrigerant, leading to better absorption of heat.

This improved heat transfer efficiency can be beneficial in certain scenarios, especially in large-scale systems like industrial refrigeration or HVAC applications. The flooded evaporator allows for maximum utilization of the coil’s surface area, improving the overall performance of the system.

However, this efficiency gain comes with its own set of risks. While a flooded evaporator can absorb heat more effectively, it can also lead to suboptimal superheat levels if not managed properly. If too much liquid refrigerant remains in the evaporator, it could lead to a reduction in the evaporator’s ability to absorb heat effectively, leading to a decrease in system efficiency. Therefore, careful balancing of refrigerant flow and superheat levels is essential to avoid these pitfalls.

Compressor Protection: The Importance of Managing Superheat

One of the primary concerns when dealing with a flooded evaporator is the protection of the compressor. Compressors are designed to handle only vaporized refrigerant, and the presence of liquid refrigerant can cause significant damage. This is why superheat is critical: it ensures that only vapor enters the compressor.

In a flooded evaporator situation, the refrigerant that exits the evaporator may not have enough superheat, which can lead to liquid refrigerant entering the compressor. Liquid refrigerant in the compressor can cause a phenomenon known as “liquid slugging,” which can damage the compressor valves, pistons, and other internal components. This can drastically reduce the lifespan of the compressor and potentially lead to catastrophic failure.

To prevent this, systems with flooded evaporators must be carefully monitored and controlled to maintain adequate superheat levels. This is often achieved through the use of superheat controls, pressure regulators, and other monitoring systems that ensure the refrigerant entering the compressor is in its vapor form.

Troubleshooting Flooded Evaporators and Superheat Issues

When issues with superheat and flooded evaporators arise, it’s important to perform a thorough diagnostic check to identify the root cause. Common causes of flooded evaporators include excessive refrigerant charge, improper expansion valve operation, and incorrect refrigerant flow. In these cases, system adjustments or repairs are necessary to restore proper superheat levels.

Some troubleshooting steps include:

Checking the expansion valve: Ensure the expansion valve is functioning properly and providing the correct refrigerant flow to the evaporator.

Inspecting the refrigerant charge: Too much refrigerant in the system can lead to flooding. Check for overcharging or leaks in the system.

Monitoring system pressures and temperatures: Measure the evaporator pressures and temperatures to ensure they align with expected superheat values.

Ensuring proper airflow: Restricted airflow over the evaporator coil can lead to poor heat transfer and excess liquid refrigerant.

By addressing these issues, technicians can restore proper superheat levels and avoid the negative effects of a flooded evaporator.

Conclusion: Balancingif evaporator is flooded the superheat will increase Flooded Evaporators and Superheat for Optimal Performance

In conclusion, when an evaporator is flooded, it can indeed lead to changes in superheat. A flooded evaporator typically results in lower superheat levels, which can enhance heat transfer but also pose risks if not managed properly. Superheat plays a critical role in ensuring that only vapor enters the compressor, protecting the system from potential damage.

While flooded evaporators can improve heat transfer efficiency, they require careful management to prevent compressor damage and maintain overall system performance. Proper system design, maintenance, and monitoring are essential to ensure the safe and efficient operation of refrigeration systems with flooded evaporators. By understanding the relationship between superheat and evaporator flooding, technicians can optimize system performance, improve energy efficiency, and extend the lifespan of critical components.