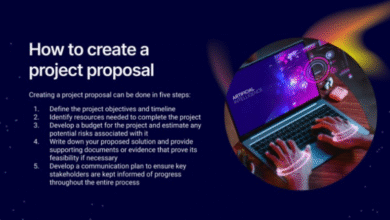

Why Compact Gear Systems Are Essential for Modern Industry

Compact gear systems are essential for streamlining industrial spaces, powering machinery like conveyor belts and lifts with efficiency and reliability. They enhance operational efficiency, reduce costs, and improve safety while saving space. This post explores their benefits, applications, maintenance tips, and future potential in industrial settings.

The Advantages of Going Compact

Opting for a compact gear system isn’t just about saving space; it’s about unlocking a range of operational benefits that can have a significant impact on your bottom line and overall efficiency.

- Space Efficiency: The most obvious benefit is the reduced footprint. In facilities where every square foot counts, smaller gear systems allow for more flexible machine design and layout. This can free up valuable floor space for other critical operations or a safer, less cluttered work environment.

- Energy Savings: Modern compact gear systems are designed for high efficiency. They transmit power with minimal energy loss, which means less electricity is needed to perform the same amount of work. Over time, these energy savings can lead to substantial cost reductions.

- Reduced Weight: Lighter components make installation, maintenance, and transportation easier and less expensive. The reduced weight can also lessen the structural load on machinery, potentially extending the lifespan of the equipment it’s part of.

- Improved Performance and Precision: Despite their smaller size, these gear systems offer high torque and precise speed control. This is critical for applications like conveyor belts that need to move products smoothly and for lifts that require exact positioning.

- Lower Noise Levels: Advanced design and manufacturing techniques have resulted in gear systems that operate much more quietly than their older, bulkier counterparts. A quieter workplace is not only better for employee well-being but can also be a requirement in certain environments.

- Cost-Effectiveness: While the initial investment might be comparable to traditional systems, the long-term savings in energy, maintenance, and space often make compact gear systems a more cost-effective choice over the life of the equipment.

Types of Compact Gear Systems

Several types of gear systems are valued for their compact design. The choice often depends on the specific requirements of the application, such as the required torque, speed, and orientation of the input and output shafts.

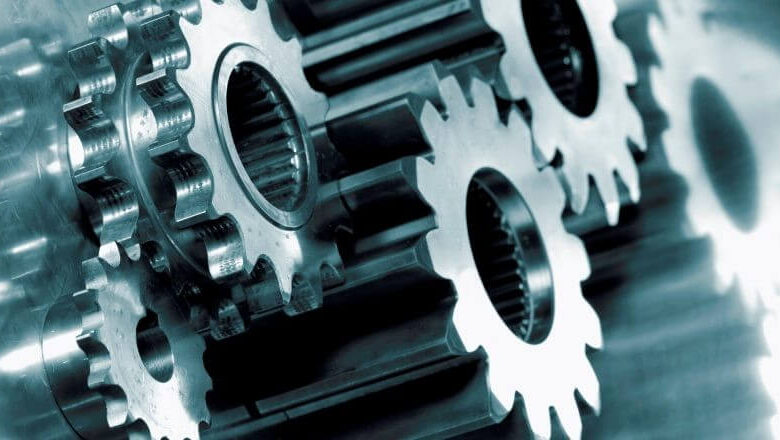

Worm Gear Systems

Worm gears are well-known for their ability to provide large gear reductions in a small package. A worm gear box assembly consists of a worm (a screw-like gear) that meshes with a worm wheel (a gear similar to a spur gear). This configuration allows for high torque transmission and is naturally self-locking, which is a significant safety feature in applications like lifts, as it can prevent the load from slipping backward if power is lost.

Planetary Gear Systems

Planetary gear systems, or epicyclic gear trains, are another excellent choice for compact, high-torque applications. They consist of a central “sun” gear, several “planet” gears revolving around it, and an outer “ring” gear. This arrangement distributes the load across multiple gear teeth simultaneously, allowing for high torque density in a very small volume. Their coaxial alignment (input and output shafts are on the same axis) also simplifies machine design.

Helical Gear Systems

Helical gears have teeth that are cut at an angle to the face of the gear. When two helical gears mesh, the contact starts at one end of the tooth and gradually spreads as the gears rotate. This results in smoother and quieter operation compared to spur gears. Compact helical gearboxes are widely used in conveyor systems where a smooth, continuous flow is essential.

Powering Conveyor Belts with Precision

In logistics, manufacturing, and distribution centers, conveyor belts are the arteries of the operation. They need to run reliably and efficiently, often for 24 hours a day. Compact gear systems are instrumental in achieving this.

A gear motor attached to a conveyor belt’s drive pulley uses a compact gearbox to reduce the motor’s high speed and increase its torque. This allows the belt to move heavy loads at a controlled, consistent pace. For example, a planetary gearbox might be used in a heavy-duty conveyor system in a mining operation, where high torque is needed to move tons of material. In a food processing plant, a quiet and smooth helical gear system would be preferred to handle delicate products without causing damage or disruption.

The space-saving nature of these systems also allows for more sophisticated conveyor designs, such as curved or inclined conveyors, without requiring bulky drive mechanisms that could obstruct the workflow.

Lifting Operations to New Heights

Lifts, elevators, and hoists rely on gear systems for safe and precise vertical movement. Here, the requirements for torque, control, and safety are even more stringent than in many conveyor applications.

Worm gear systems are particularly well-suited for lifts due to their self-locking characteristic. This inherent safety feature can prevent a lift car from falling if the motor or brake fails. Their ability to handle high loads in a compact form makes them ideal for machine room-less elevators, where all the drive equipment must fit within the hoistway itself.

Planetary gear systems are also used in high-performance lifting applications. Their high efficiency and torque density are valuable in large industrial hoists or cranes where both power and precision are critical for moving heavy and often expensive equipment or materials.

Maintenance for Maximum Longevity

While modern compact gear systems are designed for durability and low maintenance, a proper maintenance schedule is essential to ensure a long and trouble-free service life.

Key maintenance practices include:

- Regular Lubrication: Using the correct type and amount of lubricant is the single most important factor in gear system longevity. The lubricant reduces friction and wear, dissipates heat, and protects against corrosion.

- Monitoring for Vibration and Noise: Changes in vibration or noise levels can be early indicators of a problem, such as bearing wear or gear misalignment. Regular monitoring can help catch these issues before they lead to catastrophic failure.

- Temperature Checks: Overheating is a sign of excessive friction or lubrication problems. Using thermal imaging or temperature sensors can help identify hot spots.

- Visual Inspections: Regularly inspecting the gear system for leaks, loose bolts, or signs of wear can help prevent minor issues from becoming major problems.

The Next Generation of Gear Systems

The future of compact gear systems is being shaped by advancements in materials science, manufacturing technology, and smart automation. We can expect to see gear systems that are even smaller, lighter, and more efficient. The use of new alloys and composite materials will improve strength and reduce weight.

Furthermore, the integration of sensors and IoT (Internet of Things) technology is leading to the development of “smart” gearboxes. These systems can monitor their own health in real-time, predict potential failures, and communicate with a central control system to schedule maintenance proactively. This will lead to even greater reliability and less downtime in the industrial facilities of the future.

Conclusion

Compact gear systems offer high performance in a small design, making machinery more efficient, reliable, and cost-effective. They are a strategic investment for businesses using automated equipment, providing a competitive edge and playing a key role in the future of industrial technology.